In the context of how this emerging Kathmandu Valley as an metropolitan city with 40 million population is managing all the waste that is being drained from every toilet, a small approach of Mahalaxmi Municipality (Lubhu village, Lalitpur district) in the sector of Faecal Sludge Management at community level is noteworthy.

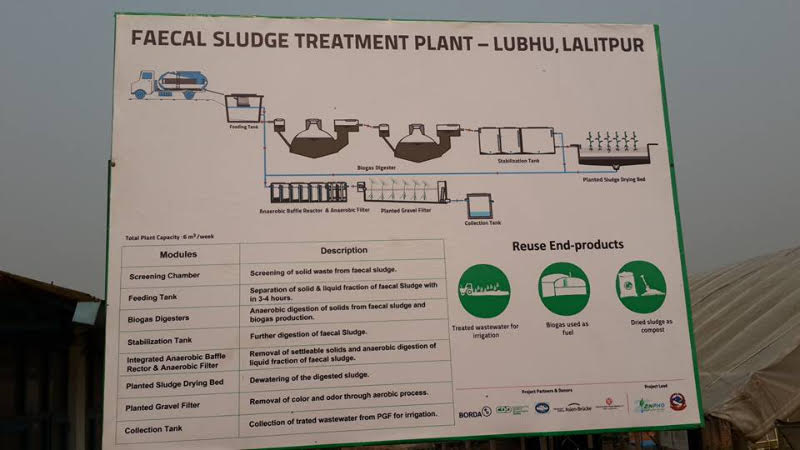

The municipality has utilized a 1-ropani land of a local child care home’s farm at Lubhu for this unique purpose - a Faecal Sludge Treatment Plant is recently established there. It looks quite ordinary when one visits this place for the first time. There is an inlet fixed just at the roadside - the vehicles, which collect sludge from septic tanks from household toilets from all over the Kathmandu Valley, bring their collection three times a week here. The stinking sludge, after going through small-scale processing unit, eventually turns into almost pure water, which is used for irrigation. What comes out meantime, as apparent profit of managing this sludge, is cooking gas for one family of the car taker. And the environmental benefit as management of the 6 cube metres of sewage per week is priceless.

Surya Ghimire, the farmer, who has been taking care of the farm says that the small but wonderful technology has been a bless in disguise for the farm he is working in. “It is nice that the bio-gas plant they have set up by the corner of the farm gives me gas for cooking for my family as wellas for the cattle I raise here. What else do I need?” he says.

He adds that the dried sludge that comes out from the reed belt could be used as manure in the farm if it is further processed.

And he hopes that such plants are set up in several other places in the Kathmandu Valley and the rivers will be clean enough to take holy bath again in near future.

Narendra Man Dangol, who was responsible for construction of the site, says it was made possible within 42 working days. It has covered around 600 square metre of land for the whole plant.

“It is an easy technology. I have to say. But as we are learning by doing, we also felt some practical problems that we are instantly correcting,” he said.

The treatment process provides resource recovery options; treated wastewater for reuse in irrigation, bio-solids as soil conditioner for farming, biogas for cooking and lighting, which benefits the treatment plant caretaker. Ultimately, the agriculture products from the treatment plant’s caretaker are primarily utilized for consumption by the kids residing in Saligram Bal Griha and excessive produce is also sold in the local market.

Sanitation engineer at ENPHO, Reetu Rajbhandari says the recently established plant is highly efficient and can be operated without any skilled labor on a day-to-day basis.

According to her, the faecal sludge treatment plant is a gravity-based system and is capable of processing 6 cube metre of sewage per week. The plant utilized a combination of prefabricated modules and locally civil constructed units to achieve cost efficiency during construction.

She adds, “The operations and maintenance requirements are relatively low and are achieved via treating sewage in the absence of electromechanical equipment.”

This treatment plant is a pilot implementation by Mahalaxmi Municipality with support from ENPHO, BORDA, Saligram Bal Griha and CDD Society. The plant is the first of its kind in Nepal with regard to the concept of reusability of all possible end products and integrated approach towards faecal sludge treatment.

Source: Water Discourse Vol. 1 Issue 1 February 2017